Every organization depends on its people doing the right things, the right way, every time. That’s what documentation like Standard Operating Procedures (SOPs) and work instructions are designed to ensure. Together, these kinds of documents translate policies into action and turn consistency into a competitive advantage. They form a foundation for getting work done.

And research shows that SOPs and work instructions genuinely make a difference. “The increasing strictness of SOPs [and related documents] and the discipline in following them can also have a positive effect on both performance and productivity,” concluded researchers in the International Journal of Business, Law and Education.

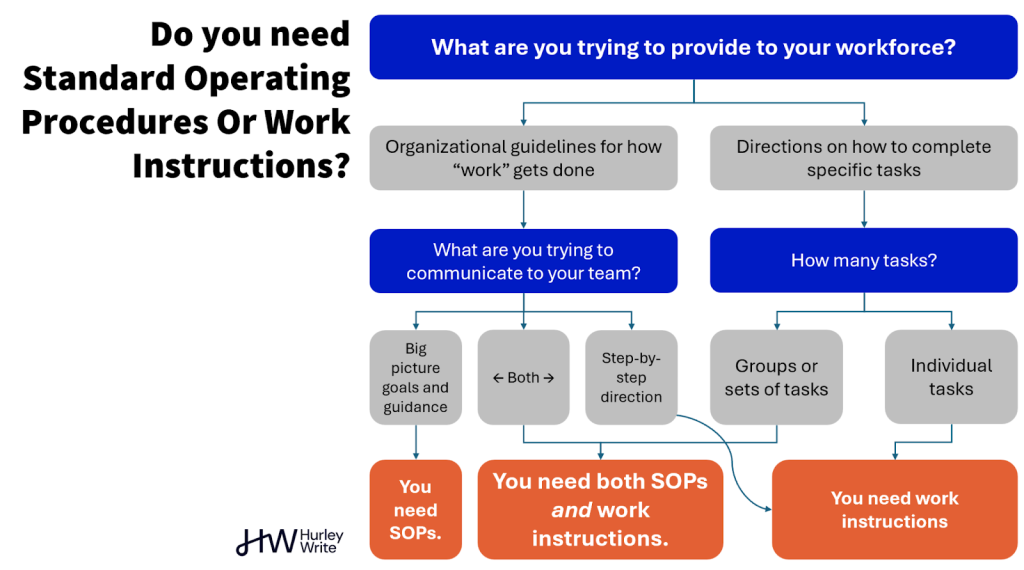

However, to maximize those positive effects, organizations need to know when to use which types of guidance. Broadly speaking, both SOPs and work instructions define how work gets done, but in practice, they each serve different functions.

How a Work Instruction vs. SOP Fits into a Larger System

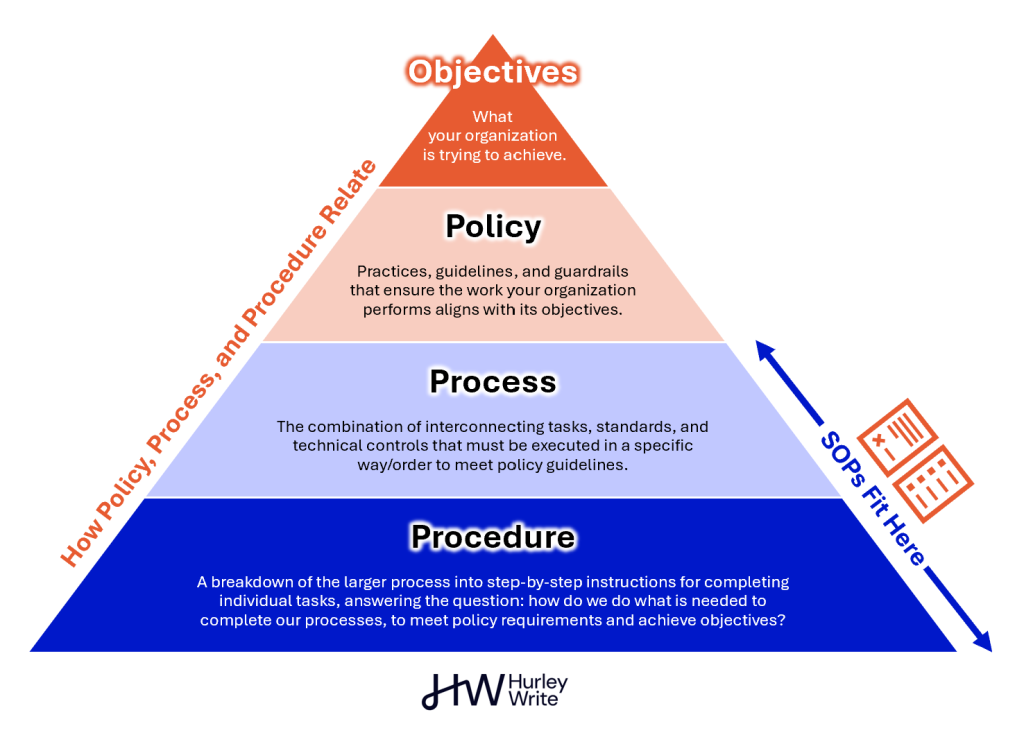

Every organization depends on a structured system of policies, processes, and procedures to translate goals into action. At the top are organization-wide objectives, the strategic outcomes the company wants to achieve. Beneath those are policies, which translate those objectives into the rules or expectations that guide behavior.

Below that layer sit processes, the repeatable activities that put those policies into motion. Finally, at the base of this pyramid are procedures or work instructions. These are the step-by-step directions that tell teams exactly how to complete each task that makes up a process.

In other words, work instructions are the procedures that support SOPs, and SOPs are the processes that support policy and strategy. Another way to think about the relationships here:

- Policies express intent “We will maintain quality through standardized production methods by ensuring that every SOP is followed and documented.”

- Processes and SOPs describe what happens, who does it, and in what order:“Inspect all products before packaging.”

- Work Instructions provide the step-by-step “how”: “Hold the caliper at 90 degrees”

The work instruction exists so the SOP can be executed consistently, without guesswork or individual improvisation. This layered approach connects the smallest routine actions on the shop floor to the organization’s highest goals. When a team member follows a well-designed work instruction, they are contributing directly to the organization’s ability to meet standards, fulfill regulations, and deliver consistent results.

When to Use a Work Instruction vs. SOP

The distinction between SOPs and work instructions isn’t about which type to use instead of the other, because they’re mutually supportive rather than mutually exclusive. Think of them as tools your team uses to solve different problems.

- Use SOPs to document a complete process or workflow. They’re ideal when tasks involve multiple people, departments, or checkpoints, such as onboarding new clients or conducting equipment maintenance. SOPs provide the overview and sequencing to manage complexity across teams.

- Use work instructions to break down individual steps within that process. They’re essential when precision, safety, or compliance depends on doing a task a specific way. For instance, if an SOP directs a technician to “calibrate the sensor,” a linked work instruction will describe the precise calibration sequence, acceptable variance range, and verification method.

Why the Difference Matters

It might seem academic to distinguish between a work instruction and an SOP, but the distinction directly affects productivity, safety, and quality.

Studies show that work instructions help reduce both physical and mental workload. One study looking at the efficacy of work instructions found they are essential to successfully manage increasing work-task complexity (in this study, this meant more product variations): “The growing number of product variants requires a higher cognitive load and increases the likelihood of human errors. Work instructions become fundamental” in managing that workload effectively.

This is particularly true for complex work tasks that, in the absence of work instructions, consume so much focus and mental engagement that they will exhaust productivity faster and increase the risk of inconsistency among tasks.

Unfortunately, other research finds that work instructions are often inadequate. “[W]ork instructions are often insufficient or unused in final assembly,” wrote researchers in a manufacturing journal. “Results indicate that operator performance … [is] affected by the presented content of information in work instructions.”

In plain language, the quality of the work instruction is pivotal to its effectiveness. This is common sense, but too many organizations think throwing together a set of vague instructions is enough. It’s not. When teams rely on vague or incomplete work instructions, they experience higher frustration, slower performance, and greater variability in outcomes. Only when instructions are clear, specific, and integrated into the larger SOP framework can teams focus on doing the work rather than figuring out how to do it.

Building a Culture of Clarity Requires Training

One key problem: far too many organizations seem to view such documentation as just paperwork when they should see it as performance infrastructure. When SOPs and work instructions are developed systematically, they create a shared language and understanding of quality, safety, and accountability. They ensure continuity when experienced team members leave and help new team members learn tasks faster.

However, few teams receive formal training in writing these documents. As a result, instructions often emerge piecemeal (written by whoever is available, without standardization or clear design) and poorly written (unclear, vague directions matched by a lack of alignment with larger SOPs).

This is why SOP and work instruction training is so valuable. By learning to write clear, consistent, and usable documents, teams reduce confusion and training time, and ultimately align everyday actions with organizational objectives. That alignment is what turns documentation into a performance driver and a catalyst for organizational success.

FAQ: Work Instruction vs. SOP

What are Standard Operating Procedures (SOPs)?

SOPs are formal documents that describe how a process should be completed from start to finish. They define responsibilities, outline the order of operations, and ensure compliance and consistency across teams.

What are Work Instructions?

Work instructions are detailed, task-level directions that tell team members exactly how to perform individual steps within an SOP. They often include specific tools, measurements, and safety requirements. A good way to think of them is that SOPs explain what to do, while work instructions show how to do it.

How do SOPs and Work Instructions Work Together?

They operate as part of a hierarchy. SOPs describe processes and work instructions provide the supporting details that make those processes repeatable and reliable. When both are clearly written, the result is consistent performance and reduced rework.

How Do You Write SOPs and Work Instructions?

Both require clear, concise writing that uses action verbs, consistent formatting, the proper graphics, and logical sequencing. SOPs, however, require more strategic thinking and problem-solving. Work instructions demand clarity and precision in directing readers through a procedure. For more guidance on how to structure and write effective SOPs vs. work instructions, see our article here, which goes into more detail about how to construct one versus the other.

Why Invest in SOP and Work Instruction Training?

Because the quality of documentation directly affects your team’s productivity, safety, and compliance. Well-written procedures reduce cognitive workload, eliminate ambiguity, and connect day-to-day work to broader organizational objectives. In particular, our SOP Writing workshop can turn your team into maestros of work process documentation.

To master more strategies for optimizing your organization’s SOPs and work instructions, contact Hurley Write for a custom, no-obligation consultation or learn more about our dedicated SOP Writing workshop.