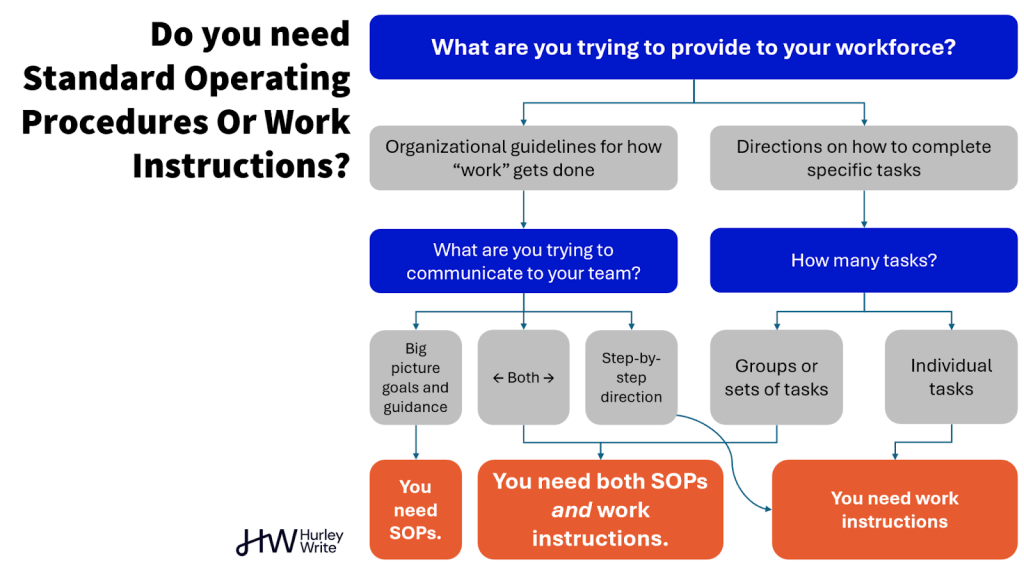

Organizations often struggle to understand whether to use work instructions or Standard Operating Procedures (SOPs), but each serves very different purposes. Choosing the right form of guidance depends on what you’re trying to communicate and at what level.

SOPs define big-picture processes, roles, and standards. Work instructions provide step-by-step guidance for completing specific tasks.

In short:

- Use SOPs for organizational guidance

- Use work instructions for task execution

- Use both when processes include multiple sets of tasks

Work Guidance Documentation Starts With Purpose, Not Type

One of the most important determinants of success at organizations with complex operating processes executed by teams is the guidance provided to those teams on how to do the work.

Different types of guidance can govern the work performed. Sometimes organizations just need high-level policy-type guardrails for legal or compliance reasons, but sometimes they need focused, step-by-step, nitty-gritty work instructions. Which type of guidance to provide is context- and goal-dependent.

In fact, the most common mistake companies make is choosing a document format before they’ve clearly defined what they’re trying to provide to their workforce. The first question shouldn’t be “Do we need work instructions or. SOP guidance?” It should be, “What are we trying to communicate?”

In this blog, we’ll walk through scenarios where one or the other (work instructions or SOP) makes more sense.

When SOPs Work Best

SOPs are best suited for situations where consistency, governance, and alignment matter more than mechanical detail.

“Effective SOPs promote consistency in implementing processes or procedures (even when there are personnel changes) and may increase efficiency through reduced employee workload,” write the authors of a guidebook on using SOPs to promote safety, quality, and consistency in the food industry. As they explain, SOPs are thorough in specifying the “who, why, what, where, when, and how.” They provide a shared framework so that work can be performed consistently, even when the day-to-day execution varies.

In other words, an SOP answers questions such as

- What is the objective of this process?

- Who is responsible for each part?

- When does the process start and end?

- What rules, controls, or standards apply?

In regulated industries, SOPs also play a critical role in compliance and audit readiness. They establish the “official” way work is supposed to be done.

Because they offer broader guidance, SOPs also have an advantage over work instructions: they tend to be more generalizable.

In an experiment, researchers compared how computer novices used work instructions focused more on mechanics versus SOPs focused on more broadly understanding the computer system: “Computer novices, in this study, were able to follow specific instructions for using a word processor more easily than general instructions.

However, they had great difficulty generalizing the specific instructions to novel tasks.”

Example: A Food Manufacturing Company Managing Regulatory Compliance and Quality Standards

A regional food manufacturer operates multiple production lines and distributes products across several states. The company must comply with strict food safety regulations while also maintaining consistent product quality, regardless of shift, facility, or personnel changes.

In this situation, the organization’s primary challenge isn’t teaching employees how to perform individual tasks on the production floor or in the kitchen. That training already exists. The real risk lies in inconsistency and noncompliance.

What the company needs are SOPs that clearly define:

- Food safety standards and regulatory requirements

- Quality control checkpoints and documentation expectations

- Roles and responsibilities for sanitation, inspection, and reporting

- Escalation and corrective action procedures when standards aren’t met

SOPs provide the governance, accountability, and consistency required in a regulated environment. The value comes from alignment and consistency, not micromanagement. This is a classic example where work instructions versus. An SOP resolves clearly in favor of SOPs.

When Work Instructions Work Best

Work instructions are most effective when mechanical clarity and precision are essential. They’re designed for individual tasks or tightly defined actions, especially when mistakes are costly or training time needs to be minimized.

Think about the role of work instructions versus SOPs in terms of cognitive load. How much mental work are you making your teams do? Work instructions tend to reduce cognitive load. As other researchers have found, “the growing number of product variants requires a higher cognitive load and increases the likelihood of human errors. Work instructions become fundamental” in managing that workload effectively.

That’s because a good work instruction doesn’t describe the entire process. It focuses on how to perform a specific task correctly, every time. That might include screenshots, numbered steps, decision points, or safety warnings.

So, if you’re onboarding new employees, rolling out new tools, or standardizing repeatable tasks, work instructions often deliver more immediate value than an SOP alone. They reduce ambiguity and help employees move from “I understand the process” to “I can do this correctly.”

The downside is that the information contained in work instructions will be less generalizable and transferable to other functions, processes, or tasks.

Example: A Warehouse Rolling Out a New Picking System

A distribution center implements a new handheld scanning system for order picking. The overall warehouse process remains unchanged, but the way employees execute a specific task has changed significantly. New hires and experienced workers alike struggle at first. Errors spike. Training supervisors spend most of their time answering the same questions repeatedly.

This is a scenario where task-level work instructions excel by showing step-by-step:

- How to log into the scanner

- The exact sequence for scanning items and locations

- What error messages mean and how to resolve them

- When to pause and request supervisor support

An SOP explaining the warehouse’s fulfillment philosophy or larger operational processes would add little value here. Employees need clear, visual, step-by-step directions. In the work instructions versus SOP decision, this scenario strongly favors work instructions alone.

When You Need Both

In many real-world scenarios, however, the answer isn’t either/or. It’s both.

If you’re dealing with groups or sets of related tasks, an SOP provides the overarching structure, while work instructions handle execution at the task level. The SOP explains how the process fits into the organization’s goals and controls.

The work instructions explain exactly how to perform each component of that process. This layered approach prevents SOPs from becoming bloated with unnecessary detail and keeps work instructions from floating around without context.

Example: A Healthcare Organization Managing Patient Intake

A multi-location healthcare provider wants to standardize patient intake across clinics while complying with regulatory requirements and maintaining a consistent patient experience. At a high level, the organization needs SOPs to define:

- The purpose of the intake process

- Required documentation and compliance controls

- Data privacy responsibilities

- How intake connects to billing and clinical workflows

But that’s not enough. Front-desk staff also need work instructions that explain:

- How to enter patient data into the system

- How to verify insurance information

- What to do when information is missing or inconsistent

- How to handle exceptions or edge cases

Here, SOPs provide structure and governance, while work instructions enable accurate execution. Without both, either compliance or efficiency breaks down.

Why Training in Work Instruction and SOP Writing Makes a Difference

Knowing when to use SOPs and when to use work instructions is only part of the challenge. Writing them effectively is another matter entirely. Far too many teams inadvertently write SOPs that read like task manuals or work instructions that drift into policy language.

Structured training in SOP and work instruction writing helps teams recognize nuance, handle edge cases, and design documentation that fits their specific operational reality. Even better, customizable workshops ensure bespoke instruction helps organizations develop the exact guide of processes and documents that reflect how their work actually happens.

If you’re serious about improving business communication, investing in training is one of the most reliable ways to master work instructions versus SOPs and ensure both tools achieve their intended purpose.

To get started with identifying which kind of guidance you need for your team and then how to write it to be maximally effective, learn more about Hurley Write’s SOP Writing workshop for business professionals.

FAQs

Can an SOP include step-by-step instructions?

Absolutely, but only in cases where both SOPs and work instructions are appropriate to provide. When SOPs include step-by-step directions, the author is simply combining both work instructions and an SOP into a single document.

That said, distinguishing the two remains important. When SOPs become overloaded with detailed task steps, they can lose clarity, and the information can become less generalizable and transferable.

In most cases, separating SOPs from work instructions creates cleaner, more effective documentation. This distinction is central to using work instructions vs. SOP guidance correctly.

How do I know whether my team needs SOPs, work instructions, or both?

Start by asking what problem you’re trying to solve. If the issue is inconsistency, accountability, or compliance, SOPs are often the right solution. If the issue is execution errors, training gaps, or task confusion, work instructions are usually more effective.

When you’re dealing with complex processes made up of multiple tasks, the answer is often both. This decision framework sits at the core of work instructions vs. SOP documentation.

Why do organizations struggle to write effective SOPs and work instructions?

Most teams were never trained to write them differently or to write them at all! SOPs and work instructions serve distinct purposes and require different structures, levels of detail, and writing styles. Without training, documents often blur together, reducing their effectiveness.

Learning how to approach work instructions versus SOP writing intentionally helps organizations create guidance that actually supports how work gets done.